Private Sale

On behalf of the beneficiaries we are selling the machines and facilities of Präzisionsteile Dresden GmbH & Co KG from Dresden in a Private Sale on our auction platform.

Approx. 15 lots are available for immediate sale, including CNC turning and grinding cell, vertical single-spindle turning and grinding centre, vertical twin-spindle turning and grinding centre, CNC milling machines, thread rolling machine, CNC machining centers, CNC external cylindrical grinding machine, pneumatic punch etc. Please see below for further details.

Online registration/bid submission now open

on our secure Auction Platform

Bids until Tuesday, September 16, 2025

Lots close upon bid acceptance. Subject to prior sale.

Written Bid Submission Form

Credit Confirmation Form

By appointment

Präzisionsteile Dresden GmbH & Co KG

Enno-Heidebroek-Str. 7

D–01237 Dresden

Google Maps »

By appointment

Präzisionsteile Dresden GmbH & Co KG

Enno-Heidebroek-Str. 7

D–01237 Dresden

Google Maps »

Auction Details

This Private Sale consists of 12 Lots:

Lot 4: 1 Vertical Single-spindle Turning and Grinding Centre EMAG VLC 200 GT, YOM 2021, Serial no. 11478, control system, manufacturer Siemens, type Sinumerik 840Dsl, workpiece diameter 200 mm, workpiece length 100 mm, main spindle 18 KW, speed 3,000 rpm, 12-station tool turret, 2 motorised grinding spindles 140/45,000, dressing unit, workpiece transport system, 21 workpiece carrier pallets, chip conveyor, emulsion mist extraction, cooling lubricant supply, paper belt filter, magnetic pre-separator, inline tool measurement, Simenes Profinet handling system interface, double piston clamping cylinder, clamping chuck

Starting Price: 150.000,00 EUR

Lot 3: 1 Vertical Twin-spindle Turning and Grinding Centre EMAG VLC 200 GT, YOM 2021, Serial no. 11479, control system, manufacturer Siemens, type Sinumerik 840Dsl, workpiece diameter 200 mm, workpiece length 100 mm, main spindle 18 KW, speed 3,000 rpm, 12-station tool turret, external grinding spindle TSE 200, dressing unit, workpiece transport system, 21 workpiece carrier pallets, chip conveyor, emulsion mist extraction, 2x cooling lubricant supply 8/30 bar, paper belt filter, magnetic pre-separator, inline workpiece measurement, Simenes Profinet handling system interface, double piston clamping cylinder, flange clamping mandrel

Starting Price: 150.000,00 EUR

Lot 10: 1 CNC-Milling Machine FANUC Robodrill Alpha D21MiB 5, YOM 2019, Serial no. P18YZG241, control, type 31I model B5, table size 650 x 400 mm, travel range X/Y/Z 500 x 400 x 330 mm, rotary table, manufacturer Lehmann TF-507510. RR TIP 1C, centre height 180 mm, 3-jaw chuck Schunk, TH 110-2521-fold tool turret, tool holder BBT30, speed max. 24,000 rpm, chip conveyor, NOP coolant system, IKZ 70 bar, CO2 extinguishing system, HEXAGON measuring probe, Hydac hydraulic system, switch and control cabinets

Starting Price: 48.000,00 EUR

Lot 9: 1 CNC-Milling Machine FANUC Robodrill Alpha D21MiB 5, YOM 2018, Serial no. P18YZG240, control, type 31I model B5, table size 650 x 400 mm, travel range X/Y/Z 500 x 400 x 330 mm, rotary table, manufacturer Lehmann TF-507510. RR TIP 1C, centre height 180 mm, 3-jaw chuck Schunk, TH 110-2521-fold tool turret, tool holder BBT30, speed max. 24,000 rpm, chip conveyor, NOP coolant system, IKZ 70 bar, CO2 extinguishing system, HEXAGON measuring probe, Hydac hydraulic system, switch and control cabinets

Starting Price: 48.000,00 EUR

Lot 8: 1 Thread Rolling Machine ESCOFIER SA Flex M20-2, YOM 2016, Serial no. 20062, rolling force 20 t, shaft diameter max. 69.85 mm, shaft length 100–160 mm, diameter max. rolling jaws 220 mm, PLC control, manufacturer Siemens, touch display, Simatic HMI, cooling/lubricant system, 1 set of rolling jaws

Starting Price: 25.000,00 EUR

Lot 32: 1 CNC-Machining Center MAZAK VTC-200B-II, YOM 2006, Serial no. 181504, control, type Mazatrol 640M, clamping table 1,500 x 500 mm, X/Y/Z travel 1,120 x 510 x 510 mm, table load max. 800 kg, spindle speed max. 12,000 rpm, 24-station tool changer, 3 high-pressure vises +++ ATTENTION: Stored at Stiglitz in 73614 Schorndorf - pick up there! +++

Starting Price: 14.700,00 EUR Minimum Price: 21.000,00 EUR

Stiglitz Schorndorf Under reserve

Lot 48: 1 CNC-Machining Center HAAS TM-2P, YOM 2011, Ser. No. 1082539, clamping table 1,450 x 270 mm, travel X/Y/Z approx. 900 x 400 x 400 mm, 12-station tool changer, coolant supply, control, chip conveyor, ejector left, 2 high-pressure vices. +++ ATTENTION: Stored at Stiglitz in 73614 Schorndorf - pick up there! +++

Starting Price: 14.000,00 EUR Minimum Price: 20.000,00 EUR

Stiglitz Schorndorf Under reserve

Lot 38: 1 CNC-Machining Center MAZAK VTC-200V-II, YOM 2004, serial no. 170473, control, type Mazatrol 640M, clamping table 1,500 x 500 mm, travel X/Y/Z 1, 120 x 510 x 510 mm, table load max. 800 kg, spindle speed max. 12,000 rpm, 24-station tool changer. +++ ATTENTION: Stored at Stiglitz in 73614 Schorndorf - pick up there! +++

Starting Price: 12.700,00 EUR Minimum Price: 18.000,00 EUR

Stiglitz Schorndorf Under reserve

Lot 43: 1 CNC-Machining Center MAZAK VTC-200B, YOM 2000, Serial no. 144416, control, type Mazatrol 640M, clamping table 1,500 x 500 mm, travel X/Y/Z 1,120 x 510 x 510 mm, max. table load 800 kg, max. spindle speed 12,000 rpm, 24-station tool changer, 2 high-pressure vises. +++ ATTENTION: Stored at Stiglitz in 73614 Schorndorf - pick up there! +++

Starting Price: 7.000,00 EUR Minimum Price: 10.000,00 EUR

Stiglitz Schorndorf Under reserve

Sold 1 CNC-Turning and Milling Centre TRAUB TNX65, YOM 2021, Serial no. 7060704, control, manufacturer Traub, type TX8i-S, 12 axes, bar diameter 65 mm, main spindle, counter spindle, 3x 10-station tool turret with driven tool stations, travel distances X/Z 175 x 650 mm, 3x Y-axis +/- 40 mm, 2x C-axis, main spindle speed 5,000 rpm, counter spindle speed 7,000 rpm, Bar loader, manufacturer FMB, type Turbo 5-65, serial no. 410750, cooling lubricant system, high-pressure pump, belt filter, chip conveyor, CO2 extinguishing system, manufacturer Kraft + Bauer, operating hours 10,257 - subject to prior sale -

Starting Price: 200.000,00 EUR

Sold 1 CNC-Centreless Grinding Machine TSCHUDIN ecoLine 400 CNC, YOM 2015, Serial no. 15.E400.195, control, manufacturer Fanuc, type Oi-M, 3 axes, grinding diameter for through-feed grinding 100 mm, grinding diameter for plunge grinding 150 mm, grinding wheel dimensions Ø 400 x 280 mm, dressing spindle AGE 80.02-6000, dressing diamond for grinding wheel/control wheel, balancing device ELASO ebg 1500, inline measuring device, manufacturer Stotz, year of manufacture 2017, serial no. 18564, robot cell, manufacturer HT, type SRZ200/7-14P, year of manufacture 2016, serial no. 141213424, dimensions W/D 800 x 2,200 mm, 2 robots, manufacturer Fanuc, type 200iD/7L, robot control, touch hand-held terminal, drawer storage for 14 pallets, pallet size W/D/H 400 x 600 x 60 mm, SPC ejection, cabin VSG glass, safety devices

Starting Price: 110.000,00 EUR

Sold 1 CNC-Grinding Machine TSCHUDIN ecoLine 400 CNC, YOM 2014, Serial no. 14.E400.174, control, manufacturer Fanuc, type Oi-M, 3 axes, grinding diameter through-feed grinding 100 mm, grinding diameter plunge grinding 150 mm, grinding wheel dimensions Ø 400 x 280 mm, dressing spindle AGE 80.02, dressing diamond for grinding wheel/control wheel, balancing system, made by Elaso, ebg 1500, inline measuring device, made by Stotz, year of manufacture 2016, serial no. 20165, camera (image processing), made by Opto Engineering, robot cell, manufacturer HT, type SRZ300/3x7 XL, year of manufacture 2016, serial no. 15000223, dimensions W/D 1,300 x 2,700 mm, 3 robots, manufacturer Fanuc, type 200iD/7L, robot control, hand-held terminal touch, 17-fold pallet memory, pallet size 400 x 300 mm, SPC ejection, cabin VSG glass, safety devices

Starting Price: 110.000,00 EUR

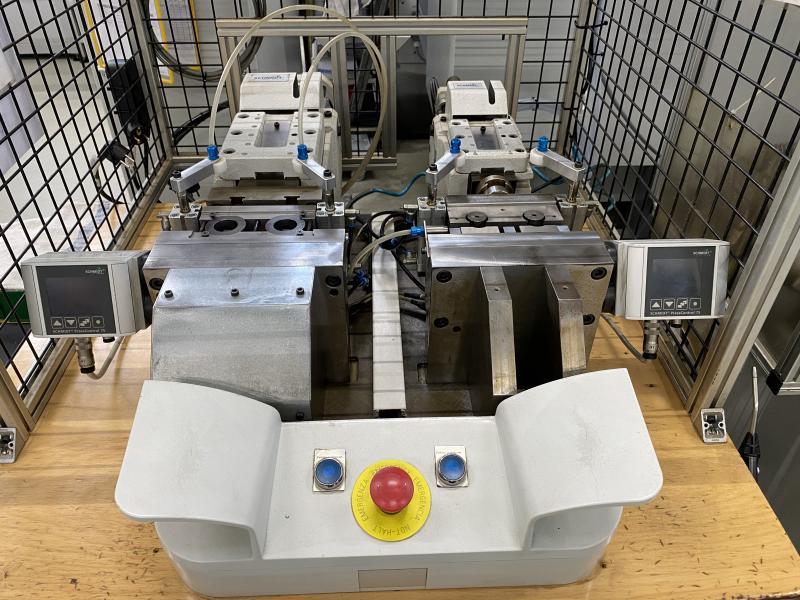

Sold 1 CNC-Notching/straightening Machine ORTLIEB KBH-ASPH 02-150, YOM 2013, Serial no. 16160, core unit, manufacturer Schoch, type SERCA, PLC system control, manufacturer Siemens, touch panel, automation, 3 industrial robots, manufacturer Fanuc, type 200IC and 200ID, each with control and programming terminal, material storage, plexiglass enclosure, control cabinet, manufacturer Rittal, light barriers, touch panel, manufacturer IP Coswig, year of manufacture 2013, serial no. K170324, sorting station, NIO ejector - Subject to prior sale -

Starting Price: 30.000,00 EUR

Sold 1 CNC-Lathe TRAUB TNL18, YOM 2011, Serial no. 6050219, control system, type TX8i-S, 9 axes, main spindle, counter spindle, 2x 12-station tool turret, driven tool stations, 2x Y-axis, 2x C-axis, chip conveyor, cooling lubricant system, belt filter, CO2 extinguishing system, manufacturer Kraft + Bauer, bar loading magazine, manufacturer FMB, type Turbo 3-26/3200, year of manufacture 2008, conveyor belt, sorting table. Operating hours spindle ON 34,411; production time 37,839.

Starting Price: 30.000,00 EUR

Sold 1 Laser Marking Cell SIM Classic Advanced, YOM 2022, Serial no. 2011474_1, interior dimensions W/D 600 x 720 mm, door opening W/H 620 x 370 mm, Z-axis adjustment range 300 mm, MD-AD-2DR scanner, extraction unit, manufacturer Fuchs, type KKF320L – as good as new, never used

Starting Price: 15.000,00 EUR

Sold 1 Laser Marking Cell SIM Classic Advanced, YOM 2022, Serial no. 2011474_2, interior dimensions W/D 600 x 720 mm, door opening W/H 620 x 370 mm, Z-axis adjustment range 300 mm, MD-AD-2DR scanner, extraction unit, manufacturer Fuchs, type KKF320L – as good as new, never used

Starting Price: 15.000,00 EUR

Overview

Präzisionsteile Dresden GmbH & Co KG

D–01237 Dresden

September 16, 2025

Private Sale

approx. 15 lots

Links & Information

- Lots close upon bid acceptance

- Subject to prior sale

- Written Bid Submission Form

- Credit Confirmation Form

- Entry Certificate Form

- Terms & Conditions

Contact

Matthias Mewes

Partner

T +49 (0)40 - 469 666-70

F +49 (0)40 - 469 666-80

M +49 (0)151 - 240 638 59

mewes@lueders-partner.com

Categories

CNC-External Cylindrical Grinding MachineCNC-Machining Center

CNC-Milling Machine

CNC-Turning and Grinding Cell

Pneumatic Punch

Private Sale

Thread Rolling Machine

Vertical Single-spindle Turning and Grinding Centre

Vertical Twin-spindle Turning and Grinding Centre